1、OVERVIEW

The Burner boom is mainly applied to burn the crude oil and natural gas discharged from the well which can not be collected properly.

In this case, the burner boom includes foundation, trestle, burner and a water nozzle system in a radial pattern heat shield.

This system is based on the design of offshore drilling modules and the offshore oil drilling equipment to fully meet operational requirements of the test oils. The system integral installation and the disassembled are convenient.

To guarantee that the burner can run normally under all kinds of oil test conditions, the burner uses three groups of burner heads, each group of burner head is controlled by ball valve with the biggest crude handling capacity of 12000bbl/d. However, according to the actual demand, ball valve can be used to control the opening state of burner head, so as to control the function of burner head. The burner heads can combine freely to satisfy the requirements for oil and gas handing capacity of 4000bbl/d~12000bbl/d; Furthermore, the burner can burn completely with neither oil drop nor smoke and dust during working, so as to bring environment protection function truly.

2、Type of booms

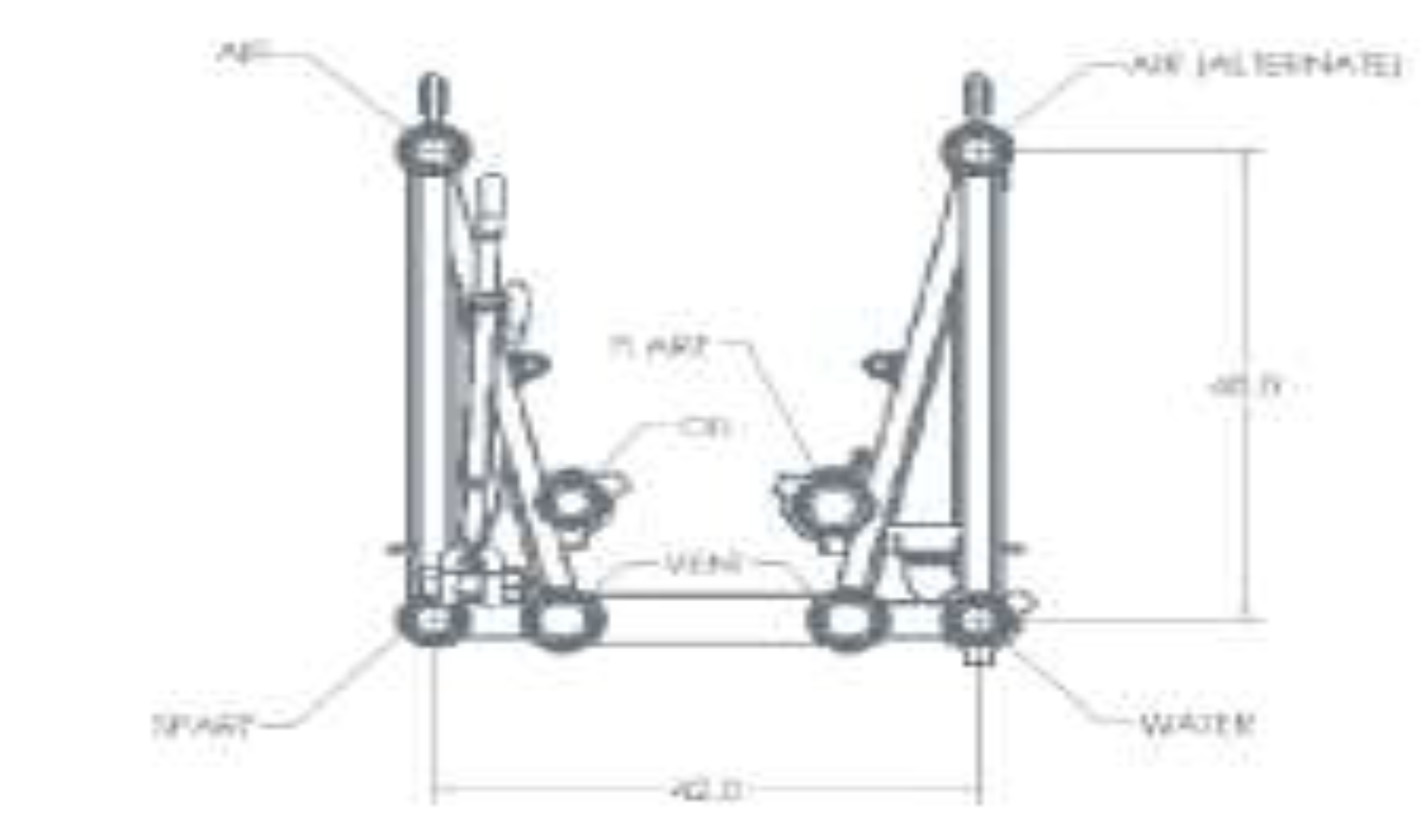

' U ' Boom

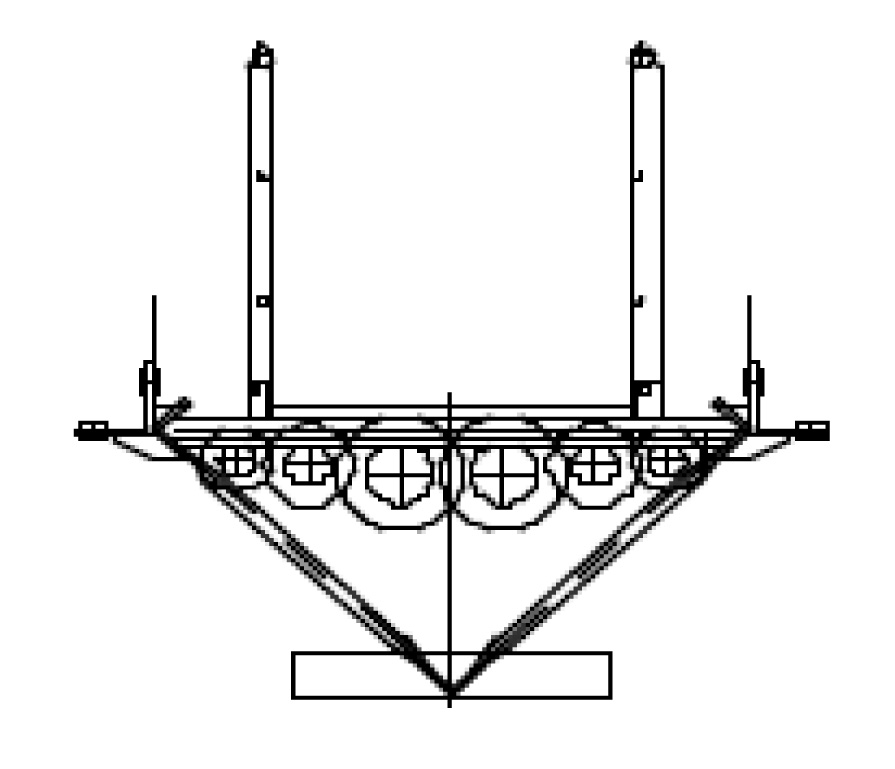

' Triangular ' Boom

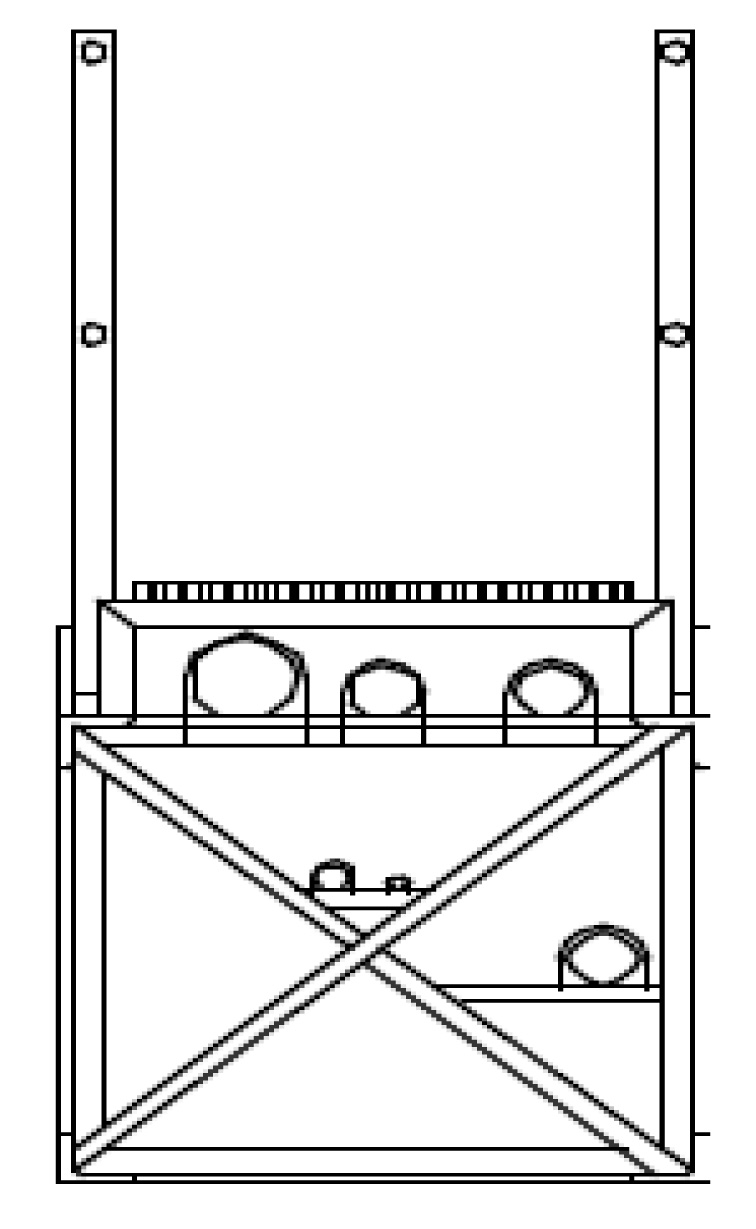

'Box' Boom

3、 The Burner

The burner is composed of burner heads, pipe-line control valve, burner support, liquefied petroleum gas nozzle, HV ignition box, spark plug, HV ignition cable, water curtain ring, flameproof enclosure, etc. The burner is installed at the end of testing oil boom to ensure the safety of testing oil.

4、Manufacturing process

5、Installation process